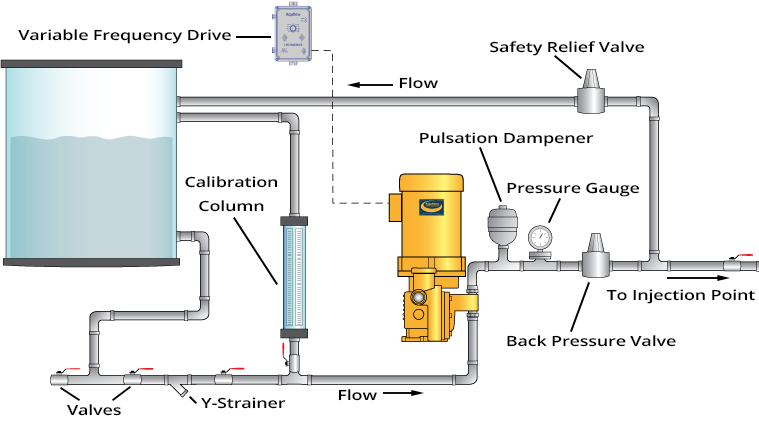

AquFlow Pump & Chemical Feed System Accessories

Aquflow strongly suggests using a back pressure valve, pressure gauge, inlet strainer, and calibration column with metering pumps to maximize life and efficiency. Your system may also require safety relief valve, and pulsation dampener depending on the application. Please ask us to quote these compatible accessories.

Back Pressure Valve (BPV)

Mounting back pressure valve on the discharge line will ensure holding a constant pressure for the discharge check assembly on the metering pump, this allows for the repeatability of a constant fluid discharge per stroke, and accuracy desired.

Safety Relief Valve (SRV)

When using a motor driven pumps or Hydraulic diaphragm metering pumps capable of higher pressure than your discharge line pressure. Safety Pressure Relief Valve must be installed to prevent over pressure of happening in the discharge line. Installation of Safety Relief valve must be in the line closest to the discharge of the pump and ensure that there are no isolation valves or components capable of closing the discharge line off prior to the relief valve.

Pulsation Dampener

In some applications pulsation is a problem, typically with most of the metering pumps. Pulsation dampener helps remove a high degree of pulsing and surging in the line. They only work if installed properly, in the right order in the line, and with the right pressure bladder to offset the incoming pulsing. It is important that the directions supplied by the manufacturer regarding recommended set pressure and location of the dampener be adhered to.

Calibration Column (Cylinders)

Aquflow offers calibration columns to calibrate metering pumps and make sure that it reaches their desired flow rate. Choosing calibration column should be based on the flow rate and the chemical compatibility to the fluid.

Pressure Gauge

Pressure gauge is a pressure indicator, where you can read your discharge pressure to make sure that it’s within the desired pressure. It comes in different sizes based on customers’ applications. It comes with gauge isolator to separate its internal component from the chemicals.

Inlet Strainer

Strainer has a very important role in the chemical metering pumps; it is mounted on the suction line, it prevents any debris or impediments to reach check valves and cause clog. This will affect the accuracy and life of the pump.

Strainers should be replaced and checked periodically to make sure that it is in a good condition and there is no debris or any impediment that can stop the chemicals flowing.