Back Pressure Valve (BPV) - AquFlow Metering Pumps

AQU Valve is a diaphragm style two port back pressure/pressure sustaining valve designed to provide and control a continuous pressure on the discharge side of a positive discharge style pump, such as metering pumps. AQU Valve assists with the proper seating of the valve check assembly and accurate filling of the pump housing chamber for a more efficient and accurate running pump. (Factory set @ 50 psig /345kPa)

Standard Features:

- No moving parts in wetted chamber; superior choice for “dirty” fluid applications .

- High flow capacity with lower pressure drop.

- Optional diaphragm materials.

- Color coded caps indicate size.

- Sizes ¼” to 4” (8 DN to 100 DN).

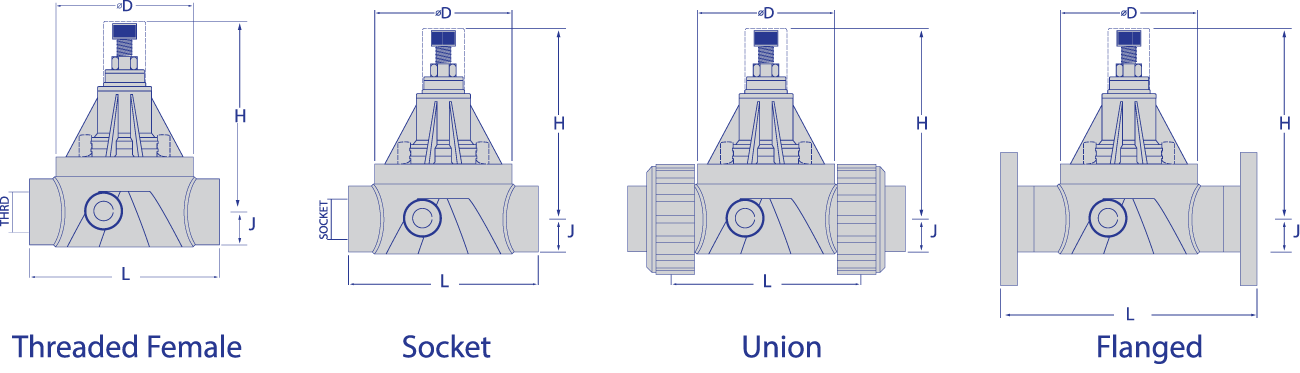

- 10 configurations: threaded, socket, union and flanged.

- Injection mould design with fewer moving parts.

- High ambient temperature ranges.

- Gauge port available in either flow direction.

Dimensional Drawings

PVC, CPVC, PP, & PVDF Back Pressure Valves

| NPS | Series | Ø D | J | H | L (Thread) | L (Socket) | L (Union) | L (Flanged) |

|---|---|---|---|---|---|---|---|---|

| 1/4″ | A | 2.50 | 0.66 | 4.48 | 3.40 | 3.40 | N/A | 6.00 |

| 3/8″ | A | 2.50 | 0.66 | 4.48 | 3.40 | 3.40 | N/A | 6.00 |

| 1/2″ | A | 2.50 | 0.66 | 4.48 | 3.40 | 3.40 | 5.40 | 6.00 |

| 1/2″ | B | 3.50 | 0.88 | 4.80 | 4.85 | 4.85 | 6.93 | 6.96 |

| 3/4″ | B | 3.50 | 0.88 | 4.80 | 4.85 | 4.85 | 7.37 | 6.96 |

| 1″ | B | 3.50 | 0.88 | 4.80 | 4.85 | 4.85 | 7.48 | 6.96 |

| 1″ | C | 4.00 | 1.47 | 5.75 | 4.90 | 4.90 | 7.59 | 9.96 |

| 1 1/4″ | C | 4.00 | 1.47 | 5.75 | 4.90 | 4.90 | 7.88 | 9.96 |

| 1 1/2″ | C | 4.00 | 1.47 | 5.75 | 4.90 | 4.90 | 9.27 | 9.96 |

| 2″ | C | 4.00 | 1.47 | 5.75 | 4.90 | 4.90 | 9.61 | 9.96 |

316 SS Back Pressure Valves

| NPS | Series | Ø D | J | H | L (Thread) | L (Socket) | L (Flange) |

|---|---|---|---|---|---|---|---|

| 1/4″ | A | 2.50 | 0.60 | 4.47 | 2.50 | 2.50 | N/A |

| 3/8″ | A | 2.50 | 0.49 | 4.58 | 2.50 | 2.50 | N/A |

| 1/2″ | A | 2.50 | 0.60 | 4.72 | 2.50 | 2.50 | 6.25 |

| 1/2″ | B | 3.50 | 0.63 | 4.80 | 3.50 | 3.50 | 7.25 |

| 3/4″ | B | 3.50 | 0.73 | 4.80 | 3.50 | 3.50 | 7.48 |

| 1″ | B | 3.50 | 0.86 | 5.10 | 3.50 | 3.50 | 7.63 |

| 1″ | C | 4.00 | 1.05 | 5.78 | 4.00 | 4.00 | 8.15 |

| 1 1/4″ | C | 4.00 | 1.05 | 5.78 | 4.00 | 4.00 | 8.14 |

| 1 1/2″ | C | 4.00 | 1.45 | 5.83 | 4.72 | 4.72 | 9.60 |

| 2″ | C | 4.00 | 1.45 | 5.82 | 4.72 | 4.72 | 9.72 |

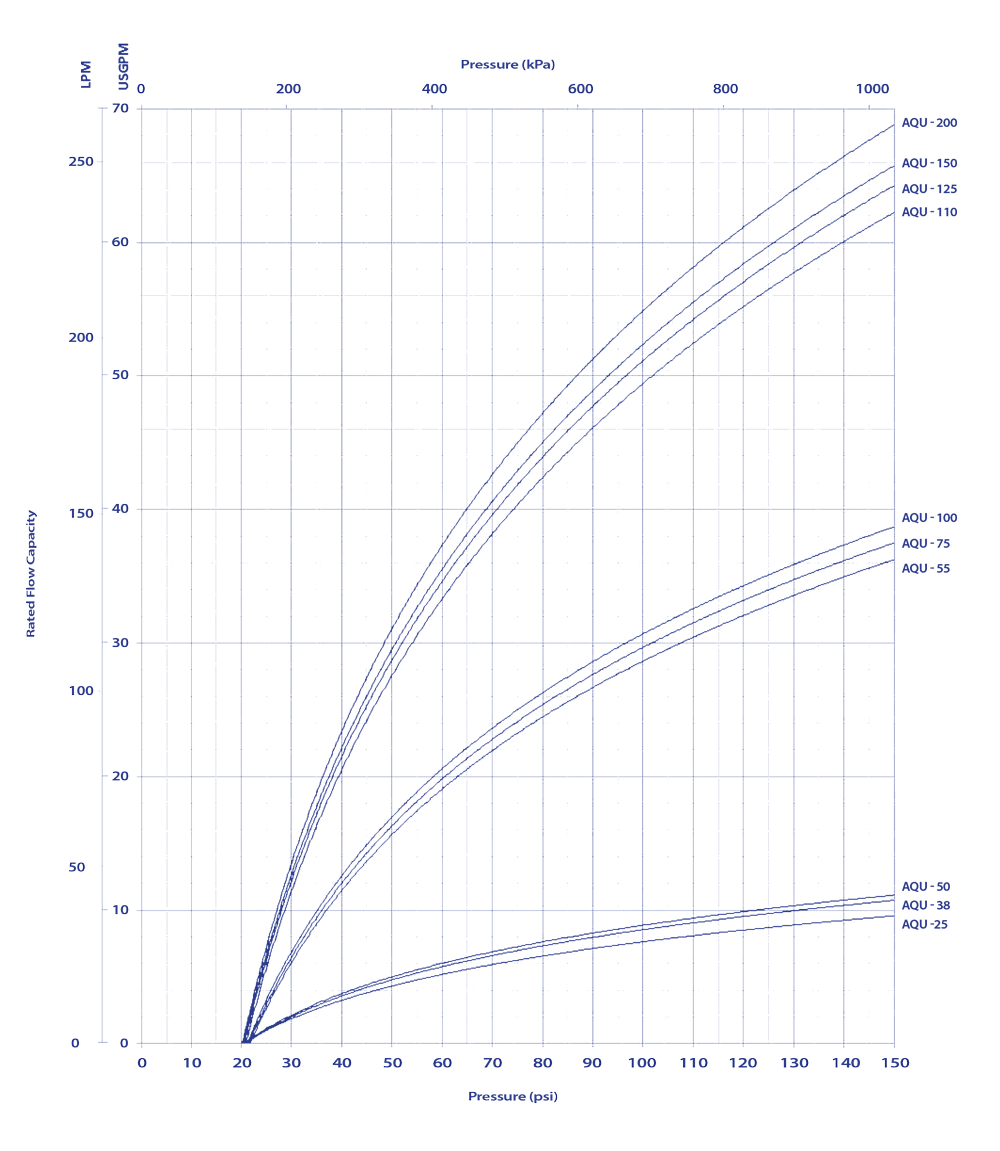

Performance Curves

The overpressure vs. flow rate curve is based on a valve spring pressure of 50 PSIG (345 kPa).

P1 = working pressure P set = 50 PSIG (345 kPa).

Example:

ECO-55 100 PSIG – 50 PSIG = 50 PSIG = 34 USGPM

690 kPa – 345 kPa = 345 kPa = 128.4 LPM

Thermoplastics Temperature Correction Factors

| F° | C° | PVC | CPVC | PP | PVDF |

|---|---|---|---|---|---|

| 70-90 | 21-32 | 1.00 | 1.00 | 1.00 | 1.00 |

| 100 | 38 | .90 | 1.00 | 1.00 | 1.00 |

| 110 | 43 | .83 | 1.00 | .91 | 1.00 |

| 115 | 46 | .75 | 1.00 | .87 | 1.00 |

| 120 | 49 | .66 | 1.00 | .83 | 1.00 |

| 125 | 52 | .58 | .97 | .79 | 1.00 |

| 130 | 54 | .50 | .95 | .75 | 1.00 |

| 140 | 60 | .33 | .90 | .66 | 1.00 |

| 150 | 66 | NR | .80 | .60 | .97 |

| 170 | 77 | NR | .60 | .43 | .86 |

| 180 | 82 | NR | .50 | .33 | .80 |

The maximum pressure rating for valves regardless of size is 150 PSIG (1034 kPa) at 73o F (22oC).

As ambient, collective surface and fluid temperature increases, the maximum valve pressure rating decreases. The decrease is dependent on the thermoplastic valve material.

Example: CPVC valve operating at 140°F (60°C) Factor at 140°F (60°C) = .90 150 PSIG x .90 = 135 PSIG

Valve is de-rated to 135 PSIG

NR = not recommended