AquFlow 4000 - Diaphragm Metering Pump

3530GPH + 3500 PSI + Highly Accurate

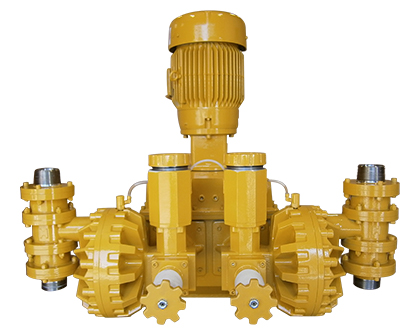

Not many pump manufacturers can boast a range of flows that start at fractional GPH and go up to 3,500 GPH. The Series 4000 diaphragm metering pumps come at the top end of this impressive pump line. Built like a battle tank, this dosing diaphragm pump is made to withstand the most brutal working conditions one can expect a pump to perform in. It balances size and boldness with precision delivering flow consistence with less than 1% variation.

Not many pump manufacturers can boast a range of flows that start at fractional GPH and go up to 3,500 GPH. The Series 4000 diaphragm metering pumps come at the top end of this impressive pump line. Built like a battle tank, this dosing diaphragm pump is made to withstand the most brutal working conditions one can expect a pump to perform in. It balances size and boldness with precision delivering flow consistence with less than 1% variation.

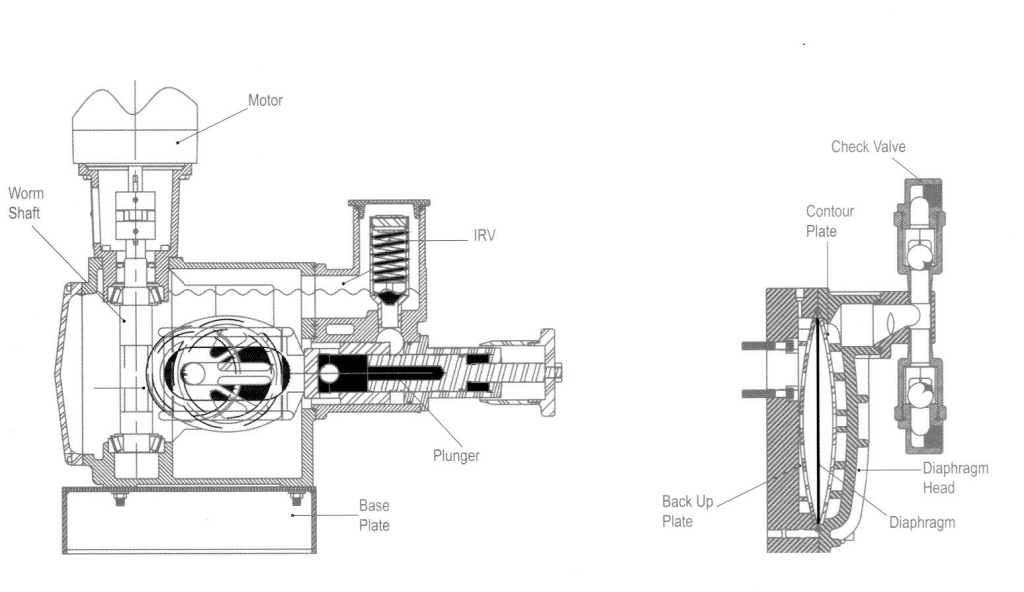

Like all other AquFlow chemical dosing pumps, this also complies with API 675 requirements. It retains all the most popular and proven design elements present in other smaller AquFlow series: a hydraulically balanced diaphragm, wear parts that all work under lubricating hydraulic oil to minimize wear and a modular design that is easy to operate, maintain and rework.

Corrosion resistance is not compromised with the liquid end available in chemical resistant materials such as 316 Stainless Steel, Alloy 20, Hastelloy C, PVC and PVDF. The metered pump also uses a disc valve which affords a larger opening to allow more viscous and some solids if needed.

Chemical Metering Pump Specifications

| Feature | Spec |

|---|---|

| Flow Capacity | Up to 3530 GPH (Duplex) |

| Pressure | Up to 3500 PSI |

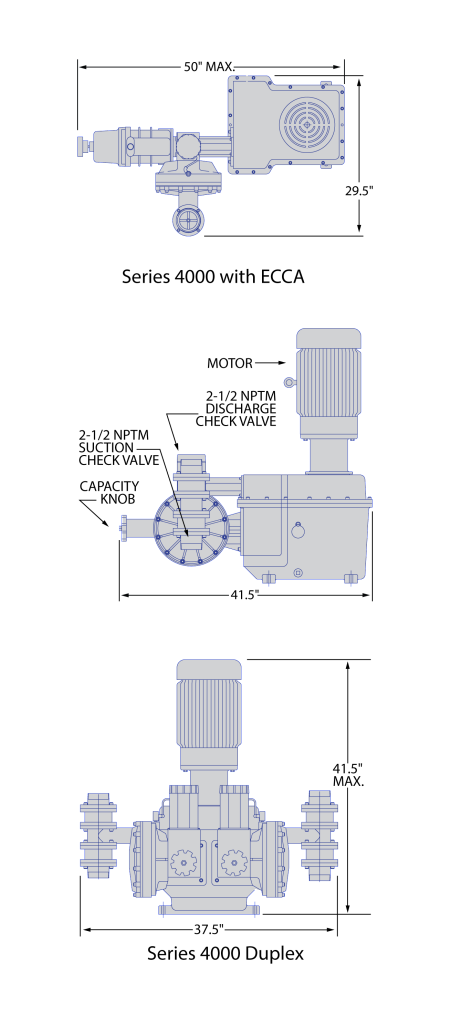

| Design | Modular design in aluminum housing |

| Metering Accuracy | +/- 1% |

| Capacity Controls | Manual/Auto |

| Safety | Built-in internal relief valve |

| Availability | Duplex or Double Flow Capacity |

| Liquid Handling | Able to handle difficult liquids like slurries, off-gasing, high viscosities |

Specifications

| Specification | Measurement |

|---|---|

| Flow Capacity Adjustment | 0–100% while the pump is running or stopped |

| Turndown Ratio | Stroke Length 10:1 Stroke Frequency 10:1 Combined 100:1 |

| Metering Accuracy | Steady State: ± 1% Linearity: ± 1% Combined: ± 1% |

| Max. Process Fluid Temp. | Custom engineered metallic liquid end: 500°F (260C) Metallic liquid end/PTFE diaphragm: 250°F (121°C) Plastic Head: 140°F (60°C) |

| Plunger Stroke Length | 6″ |

| Hydraulic Oil Capacity | – |

| Displacement Per Stroke (by plunger size) | 7/8″ – 2.2698 cu. in. (37.19 ml) 1-9/16″ – 7.6453 cu. in. (125.29 ml) 3″ – 28.1989 cu. in. (462.12 ml) 1-1/8″ – 3.8013 cu. in. (62.29 ml) 2-1/2″ – 19.63 cu. in. (321.77) 4″ – 50.34 cu. in. (824.99 ml) |

| Liquid End Material Options | 316 SS, Alloy 20, Hastelloy C, PVC, PVDF and PTFE |

Performance Table

| Pump Model Number | Capacity GPH (LPH) | Pressure psi (bars) | Speed SPM | Plunger Diameter | Connection (NPT) | Pump Curves |

|---|---|---|---|---|---|---|

| GNIT 0744-BC01A | 22.6 (85.55) | 3500 (241) | 44 | 7/8″ | 1-1/2″ | Curves |

| GNIT 0770-BC01A | 36 (136.27) | 3500 (241) | 70 | 7/8″ | 1-1/2″ | Curves |

| GNIT 0788-BC01A | 45 (170.34) | 3500 (241) | 88 | 7/8″ | 1-1/2″ | Curves |

| GNIT 0714-BC01A | 72 (272.55) | 3500 (241) | 140 | 7/8″ | 1-1/2″ | Curves |

| GNIT 0944-BC01A | 39.2 (148.39) | 2000 (138) | 44 | 1-1/8″ | 1-1/2″ | Curves |

| GNIT 0970-BC01A | 62.3 (235.83) | 2000 (138) | 70 | 1-1/8″ | 1-1/2″ | Curves |

| GNIT 0988-BC01A | 78.4 (296.78) | 2000 (138) | 88 | 1-1/8″ | 1-1/2″ | Curves |

| GNIT 0914-BC01A | 124.7 (472.04) | 2000 (138) | 140 | 1-1/8″ | 1-1/2″ | Curves |

| GNIT 1344-BC01F | 78.8 (298.29) | 1000 (69) | 44 | 1-9/16″ | 2-1/2″ | Curves |

| GNIT 1370-BC01F | 125.35 (474.5) | 1000 (69) | 70 | 1-9/16″ | 2-1/2″ | Curves |

| GNIT 1388-BC01F | 157.58 (596.51) | 1000 (69) | 88 | 1-9/16″ | 2-1/2″ | Curves |

| GNIT 1314-BC01F | 250.7 (949) | 1000 (69) | 140 | 1-9/16″ | 2-1/2″ | Curves |

| GNIT 2044-BC01F | 202.4 (766.17) | 370 (26) | 44 | 2-1/2″ | 2-1/2″ | Curves |

| GNIT 2070-BC01F | 322 (1218.9) | 370 (26) | 70 | 2-1/2″ | 2-1/2″ | Curves |

| GNIT 2088-BC01F | 404.88 (1532.64) | 370 (26) | 88 | 2-1/2″ | 2-1/2″ | Curves |

| GNIT 2014-BC01F | 644.1 (2438.18) | 370 (26) | 140 | 2-1/2″ | 2-1/2″ | Curves |

| GNIT 2444-BC01H | 291 (1101.55) | 295 (20) | 44 | 3″ | 4″ | Curves |

| GNIT 2470-BC01H | 463 (1752.65) | 295 (20) | 70 | 3″ | 4″ | Curves |

| GNIT 2488-BC01H | 582.19 (2203.83) | 295 (20) | 88 | 3″ | 4″ | Curves |

| GNIT 2414-BC01H | 926.2 (3506.05) | 295 (20) | 140 | 3″ | 4″ | Curves |

| GNIT 3244-BC01H | 519.35 (1965.95) | 160 (11) | 44 | 4″ | 4″ | Curves |

| GNIT 3270-BC01H | 826.24 (3127.66) | 160 (11) | 70 | 4″ | 4″ | Curves |

| GNIT 3288-BC01H | 1038.7 (3931.91) | 160 (11) | 88 | 4″ | 4″ | Curves |

| GNIT 3214-BC01H | 1652.4 (6255.01) | 160 (11) | 140 | 4″ | 4″ | Curves |

Capacity Control Options

- Dual Axis with both stroke length and stroke speed adjustable.

Stroke Length Controls

- Manual: Standard on all pumps.

- Electric: Electric stepper motor. Capable of 4-20mA input.

- Pneumatic: Runs on 30 PSI air for hazardous environment.

Liquid Handling Options:

Tubular

- For liquids with suspended solids/slurries that may clog. Good for high viscosity liquids also.

Degassing Valve

- Some challenging liquids can cause air locking due to off gassing. Our pump head with degassing valve ensures accurate and consistent pumping by letting our gas bubbles from the pump head.

Double Ball Check Valve

- An added measure of assurance that you have the position valve shut off.

Tungsten Carbide Valve Balls

- For abrasive liquids.

Leak Detection Options:

Leak Detection

- There are two types of leak detection options available with AquFlow pumps.

Conductive

- Conductivity probe between 2 diaphragms to sense any break or rupture.

Vacuum

- Uses a vacuum switch between 2 diaphragms to sense any rupture or failure.

Other Options:

Liquid Connections

- NPT / FLANGE / TRICLAMP

Motor Options

- Enclosure: TEFC, TENV, Explosion Proof, Washdown

- Power Supply: ACV 115V, 230V, 380V, 460V, DC-12, 24, 90, 180, Single Phase, 3-Phase