AquFlow 2000 - Diaphragm Metering Pump

224GPH + High PSI + Highly Accurate

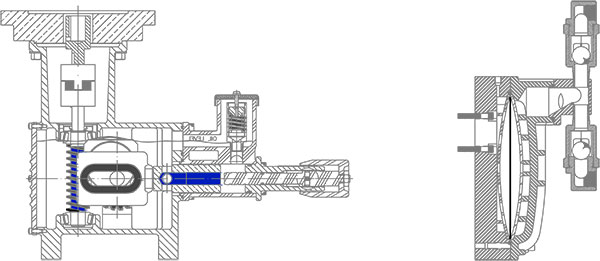

The AquFlow Series 2000 diaphragm chemical pump is a rugged, compact hydraulically actuated diaphragm metering pump. It’s designed to handle pressures of up to 1800 PSI and flow capacities up to 180 GPH.

The AquFlow Series 2000 diaphragm chemical pump is a rugged, compact hydraulically actuated diaphragm metering pump. It’s designed to handle pressures of up to 1800 PSI and flow capacities up to 180 GPH.

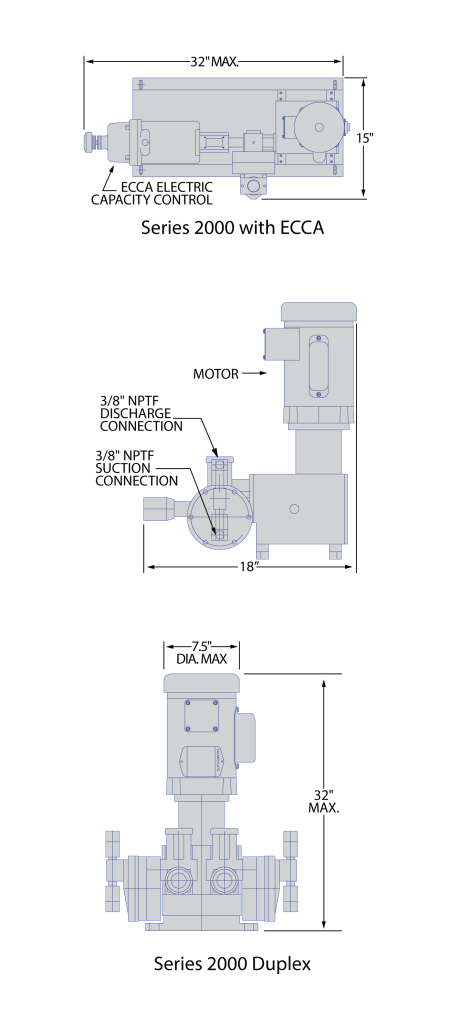

The Series 2000 diaphragm metering pump is available in simplex and duplex configurations, depending on the flow capacity needed. Its robust, modular design enables it to be used in challenging applications in a variety of industries, including municipal water treatment.

All of the Series 2000 chemical injection pumps drive parts are fully enclosed in an aluminum housing. This robust and durable design protects the most important parts from harsh environments while still being capable of handling corrosive dosing chemicals and viscous liquids. Its dependability allows it to operate for years with little maintenance. The AquFlow Series 2000 diaphragm dosing pump durability and efficiency continues to set the standard for chemical metering pumps. Complies with API 675 standards for positive displacement pumps.

Chemical Metering Pump Specifications

| Feature | Spec |

|---|---|

| Flow Capacity | Up to 224 GPH (Duplex) |

| Pressure | Up to 1,800 PSI |

| Design | Modular |

| Metering Accuracy | +/- 1% |

| Capacity Controls | Manual/Auto |

| Safety | Built-in internal relief valve |

| Availability | Duplex or Double Flow Capacity |

| Liquid Handling | Able to handle difficult liquids like slurries, off-gasing, high viscosities |

Specifications

| Specification | Measurement |

|---|---|

| Flow Capacity Adjustment | 0–100% while the pump is running or stopped |

| Turndown Ratio | Stroke Length 10:1 Stroke Frequency 10:1 Combined 100:1 |

| Metering Accuracy | Steady State: ± 1% Linearity: ± 1% Combined: ± 1% |

| Max. Process Fluid Temp. | Custom engineered metallic liquid end: 500°F (260C) Metallic liquid end/PTFE diaphragm: 250°F (121°C) Plastic Head: 140°F (60°C) |

| Plunger Stroke Length | 2″ |

| Hydraulic Oil Capacity | – |

| Displacement Per Stroke (by plunger size) | 3/4″ 0.6988 cu. in. (11.45 ml) 1-1/4″ 1.8781 cu. in. (30.77 ml) 1″ 1.1365 cu. in. (18.62 ml) 1-1/2″ 2.0822 cu. in. (34.12 ml) |

| Liquid End Material Options | 316 SS, Alloy 20, Hastelloy C, PVC, PVDF and PTFE |

Performance Table

| Pump Model Number | Capacity GPH (LPH) | Pressure psi (bars) | Speed SPM | Plunger Diameter | Connection (Metallic – NPT) | Pump Curves |

|---|---|---|---|---|---|---|

| CD3T 0529-0X014 | 2.84 (10.75) | 1800 (124) | 29 | 5/8″ | 3/8″ | Curves |

| CD3T 0558-0X014 | 5.69 (21.54) | 1800 (124) | 58 | 5/8″ | 3/8″ | Curves |

| CD3T 0597-0X014 | 9.51 (36) | 1800 (124) | 97 | 5/8″ | 3/8″ | Curves |

| CD3T 0512-0X014 | 11.47 (43.42) | 1800 (124) | 117 | 5/8″ | 3/8″ | Curves |

| CD3T 0514-0X014 | 13.73 (51.97) | 1800 (124) | 140 | 5/8″ | 3/8″ | Curves |

| CD3T 0519-0X014 | 18.73 (70.9) | 1800 (124) | 191 | 5/8″ | 3/8″ | Curves |

| CD3T 0629-0X014 | 4.7 (17.79) | 1000 (69) | 29 | 3/4″ | 3/8″ | Curves |

| CD3T 0658-0X014 | 9.4 (35.58) | 1000 (69) | 58 | 3/4″ | 3/8″ | Curves |

| CD3T 0697-0X014 | 15.7 (59.43) | 1000 (69) | 97 | 3/4″ | 3/8″ | Curves |

| CD3T 0612-0X014 | 19 (71.92) | 1000 (69) | 117 | 3/4″ | 3/8″ | Curves |

| CD3T 0614-0X014 | 22.7 (85.93) | 1000 (69) | 140 | 3/4″ | 3/8″ | Curves |

| CD3T 0619-0X014 | 30.99 (117.31) | 1000 (69) | 191 | 3/4″ | 3/8″ | Curves |

| CD3T 0829-0X014 | 7.68 (29.07) | 360 (25) | 29 | 1″ | 1/2″ | Curves |

| CD3T 0858-0X014 | 15.37 (58.18) | 360 (25) | 58 | 1″ | 1/2″ | Curves |

| CD3T 0897-0X014 | 25.7 (97.29) | 360 (25) | 97 | 1″ | 1/2″ | Curves |

| CD3T 0812-0X014 | 31 (117.35) | 360 (25) | 117 | 1″ | 1/2″ | Curves |

| CD3T 0814-0X014 | 37.09 (140.4) | 360 (25) | 140 | 1″ | 1/2″ | Curves |

| CD3T 0819-0X014 | 50.61 (191.58) | 360 (25) | 191 | 1″ | 1/2″ | Curves |

| CD3T 1029-0X014 | 12.67 (47.96) | 210 (14) | 29 | 1-1/4″ | 3/8″ M | Curves |

| CD3T 1058-0X014 | 25.35 (95.96) | 210 (14) | 58 | 1-1/4″ | 3/8″ M | Curves |

| CD3T 1097-0X018 | 42.39 (160.46) | 210 (14) | 97 | 1-1/4″ | 1/2″ F | Curves |

| CD3T 1012-0X018 | 51.13 (193.55) | 210 (14) | 117 | 1-1/4″ | 1/2″ F | Curves |

| CD3T 1014-0X018 | 61.18 (231.59) | 210 (14) | 140 | 1-1/4″ | 1/2″ F | Curves |

| CD3T 1019-0X018 | 83.47 (315.97) | 210 (14) | 191 | 1-1/4″ | 1/2″ F | Curves |

| CD3T 1229-0X014 | 14.13 (53.49) | 195 (13) | 29 | 1-1/2″ | 3/8″ M | Curves |

| CD3T 1258-0X015 | 28.25 (106.94) | 195 (13) | 58 | 1-1/2″ | 3/8″ M | Curves |

| CD3T 1297-0X018 | 47.25 (178.86) | 195 (13) | 97 | 1-1/2″ | 1/2″ F | Curves |

| CD3T 1212-0X018 | 57 (215.77) | 195 (13) | 117 | 1-1/2″ | 1/2″ F | Curves |

| CD3T 1214-0X018 | 68.19 (258.13) | 195 (13) | 140 | 1-1/2″ | 1/2″ F | Curves |

| CD3T 1219-0X018 | 93 (352.04) | 195 (13) | 191 | 1-1/2″ | 1/2″ F | Curves |

Capacity Control Options

- Dual Axis with both stroke length and stroke speed adjustable.

Stroke Length Controls

- Manual: Standard on all pumps.

- Electric: Electric stepper motor. Capable of 4-20mA input.

- Pneumatic: Runs on 30 PSI air for hazardous environment.

Liquid Handling Options:

Tubular

- For liquids with suspended solids/slurries that may clog. Good for high viscosity liquids also.

Degassing Valve

- Some challenging liquids can cause air locking due to off gassing. Our pump head with degassing valve ensures accurate and consistent pumping by letting our gas bubbles from the pump head.

Double Ball Check Valve

- An added measure of assurance that you have the position valve shut off.

Tungsten Carbide Valve Balls

- For abrasive liquids.

Leak Detection Options:

Leak Detection

- There are two types of leak detection options available with AquFlow pumps.

Conductive

- Conductivity probe between 2 diaphragms to sense any break or rupture.

Vacuum

- Uses a vacuum switch between 2 diaphragms to sense any rupture or failure.

Other Options:

Liquid Connections

- NPT / FLANGE / TRICLAMP

Motor Options

- Enclosure: TEFC, TENV, Explosion Proof, Washdown

- Power Supply: ACV 115V, 230V, 380V, 460V, DC-12, 24, 90, 180, Single Phase, 3-Phase